Hours of Operation

8:00 - 20:00

Need assistance outside of these hours? Feel free to contact our manager!

METALWORKING MACHINE TOOLS

Metalworking machine tools are the powerhouse of modern fabrication, meticulously engineered to transform raw metal into precision components and intricate structures. From high-precision lathes and powerful milling machines to versatile grinding equipment and heavy-duty presses, these essential tools deliver unparalleled accuracy and repeatability for cutting, shaping, and finishing various metals. They are indispensable for manufacturing, engineering, and specialized craftsmanship, driving innovation and quality in every metal-based industry.

BENCH GRINDERS

Bench grinders are indispensable tools for sharpening, grinding, and shaping various metal objects and tools. Mounted on a workbench, these machines typically feature two abrasive wheels that rotate at high speeds, allowing for quick material removal, deburring, and putting a fine edge on chisels, drill bits, and knives. They are essential for any workshop, providing a reliable and efficient solution for maintaining the sharpness and functionality of your tools.

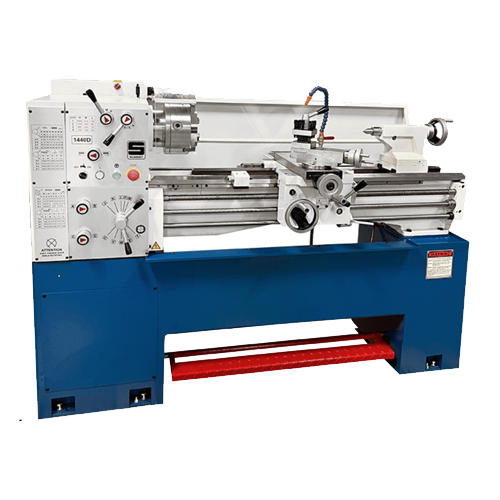

METAL LATHES

Metal lathes are precision machine tools fundamental to metalworking, designed to rotate a workpiece against a cutting tool to perform various operations like turning, facing, drilling, and threading. Essential for creating cylindrical parts, shafts, bolts, and intricate components, these robust machines offer unparalleled accuracy and versatility. They are indispensable for machinists, engineers, and manufacturers, providing the capability to craft highly precise metal parts for a multitude of applications.

METAL CHOP SAWS

Metal chop saws are powerful and robust machine tools specifically designed for making quick, precise, and straight cuts through various metal profiles, pipes, bars, and tubing. Utilizing an abrasive cutting disc that spins at high speed, these stationary saws are indispensable for fabrication shops, construction sites, and workshops that regularly work with metal, providing high efficiency and clean results for repetitive cutting tasks.

PLATE ROLLING MACHINES

Plate rolling machines are robust industrial tools designed to bend and form flat metal sheets into cylindrical, conical, or curved shapes. Essential for a wide range of fabrication, construction, and manufacturing industries, these machines utilize a series of rollers to precisely shape metal, enabling the creation of pipes, tanks, pressure vessels, and structural components with high accuracy and efficiency.

METAL SHEET BENDING MACHINES

Metal sheet bending machines are essential tools in metal fabrication, engineered to precisely bend flat metal sheets into various angles and shapes. From simple folds to complex profiles, these machines are crucial for creating components used in everything from ductwork and enclosures to automotive parts and artistic metalwork. They provide the power and accuracy needed to achieve clean, consistent bends, making them indispensable for workshops and industries that demand high-quality metal forming.

METAL MILLING MACHINES

Metal milling machines are highly versatile and precise machine tools used to remove material from a workpiece by rotating a cutting tool against it. Essential for creating flat surfaces, slots, grooves, and complex three-dimensional shapes, they are indispensable in manufacturing, engineering, and toolmaking. These robust machines offer exceptional accuracy and control, enabling the production of intricate and custom metal parts for a vast array of industrial applications.

For Full Assortment and Pricing

For our complete assortment and detailed pricing information, please contact our manager directly. They will be happy to assist you with all your inquiries and provide tailored solutions.